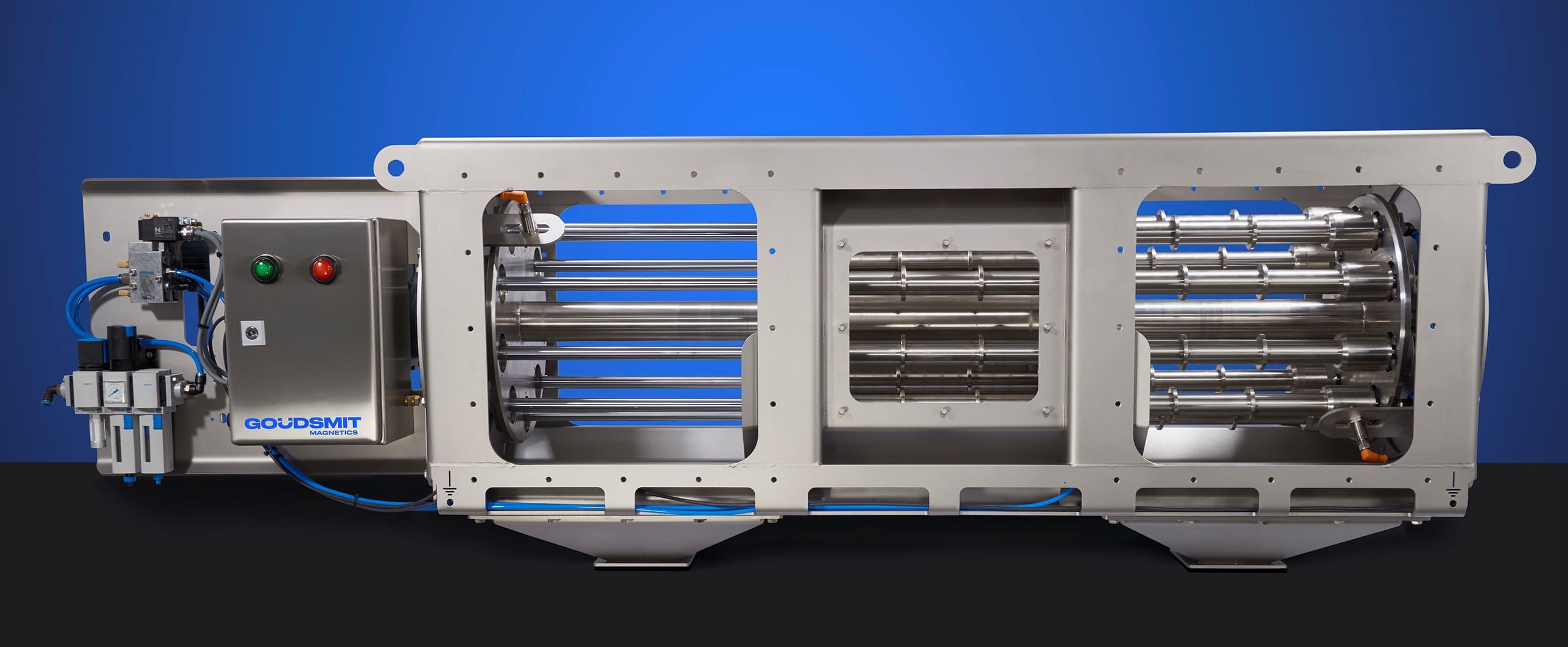

Goudsmit Magnetics rotating magnet for continuous cleaning

Here’s a solution for hard-to-reach setups or where poor-flowing powders with a relatively large amount of ferrous contamination can be automatically cleaned with rotating Cleanflow magnetic separators.

Rotating Cleanflow automatic continuous cleaning

Goudsmit Magnetics introduces the only rotary Cleanflow type that does not require a production stop to dispose of the filtered ferrous contaminants. The automatic time-controlled discharge of ferrous particles makes it suitable for product flows with a relatively large amount of ferrous contamination. Especially suitable for poorly flowing (like greasy or fatty) powders in free-fall transport lines.

The automatically controlled discharge of trapped ferrous particles makes these magnetic separators suitable for situations difficult to access for operation.

- Continuous automatic cleaning’

- Rotor with magnetic bars

- Magnetic rods in pneumatic tube (Ø34mm, 9400 gauss)

- Capacity up to 60 m³/h

Magnets stay in product flow during cleaning

The rotating Cleanflow magnetic separator separates metal particles from 30 µm from powders and granulates and is suitable for installation in free-fall lines in a continuous process. Cleaning takes place without stopping the product flow – an explicit request from a customer who wanted to recycle shredded cans of milk powder in a continuous process.

During the cleaning cycle, the magnets stay in the product flow. This guarantees no iron falls back into the product during cleaning, often a problem with other systems. The unit can be used in the chemical, ceramic, plastic, recycling industries and more. It is even used to make plastic or rubber granules metal-free.

See the Cleanflow Magnetic Separator in action

Watch how the unique Cleanflow magnetic bars rotate in the product flow. This ensures that the bars remain clean and the metal dirt comes into optimal contact with the magnets. The result is not only a high degree of separation, but also a high metal separation capacity.

Cleaning is a breeze with Cleanflow

With many magnetic separators, the magnets need to be removed from their housing during a cleaning cycle to remove trapped metal particles. This can create risks of metal falling back into the product flow so production must be suspended to clean the separator.

Not so with Cleanflow. This new system’s magnets remain in the product flow during cleaning. Only the metal-contaminated sleeves around the magnetic bars are removed together with the metal particles, subsequently replaced by clean sleeves. This makes it possible to clean the magnet without stopping production for better overall efficiency.

Stay up to date on industrial automation

OUR PRODUCTS IN ACTION

Our range of products are used by manufacturing industry throughout Australia and New Zealand with many major manufacturers specifying our tooling solutions for use in their plants. See product details by manufacturers in their specific Supplier Product Catalogues.

We’re happy to talk to you about Goudsmit Cleanflow Magnetic Separator.

Simply complete this contact enquiry and we’ll be in touch by your choice of email or phone. Thank you!