IMAO Clamping and Fixturing

Exceptional quality to standard machine elements and fixturing components are the mainstay of IMAO’s product range including their unique one-touch fasteners and work supports.

We recommend IMAO clamps for range and reliability

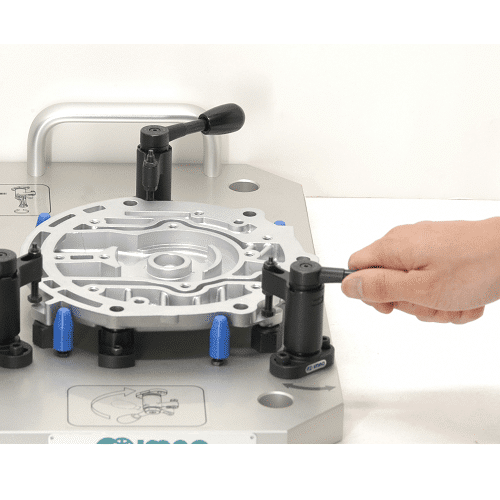

IMAO clamps help reduce the cost of workholding and fixture design with standard or modular fixture components and tombstones. Their extensive range of IMAO clamping options are ideal for machining, assembly and testing with clamps able to withstand forces up to 46kN.

All types, sizes and configurations are available to suit every application.

See the impressive range of clamping devices by IMAO of Japan, especially their ONE-TOUCH CLAMPS.

IMAO clamping to meet every application

One touch, toe clamps, side clamps, cam clamps, block clamps, hook clamps, clamp straps, retractable clamps and low profile edge clamps along with many other options.

IMAO also offers manual work supports, stops, support cylinders, screw jacks, risers, locating screws, keys, rests and contact bolts. We can help you select the components you need.

Case Study: Complicated changeover in assembling machines made simple

IMAO demonstrates how quick changeovers make a massive difference for routine work that requires various fixtures.

IMAO supplies Ball-Lock Clamps and Button-Locking Pins to Iwata Mfg, Co Ltd who manufacture machine components such as set collars and sensor brackets. These IMAO products help replace fixtures of automated production machines to assemble screws to the machinery parts body or workpieces.

Previously, this work was done by a person but because of high labour costs and mental burden for continuous simple tasks, they designed their own automated machine for purpose of reducing costs and mechanization of the simple work.

IMAO’s One-Touch Fasteners reduce workloads

This application requires “changeovers” which replace various fixtures depending on the workpiece around 10 times a day since this machine produces many products with different shapes and sizes, so they decided to use IMAO’s One-Touch Fasteners to reduce the workloads.

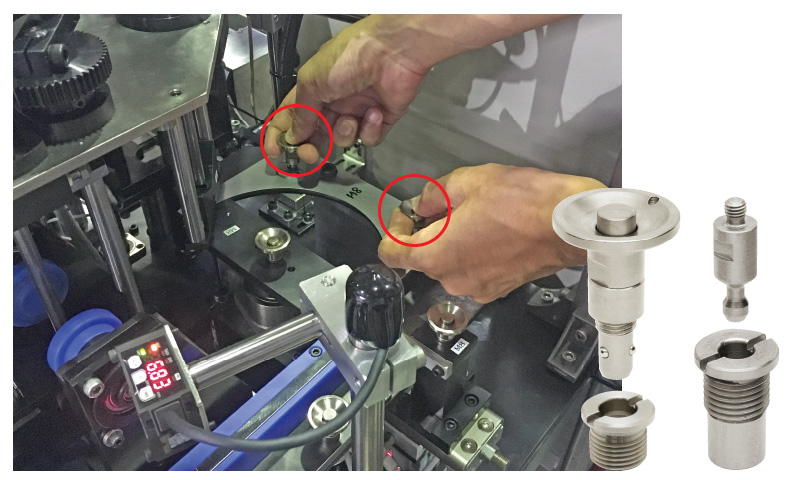

In the process of setting the workpiece that was placed in a free direction to the right position, they clamp the workpiece from either side using an air cylinder with the plastic pad and adjust it by rotating. They use Ball-lock Clamps to fix the pad to replace 11 types of plastic pads depending on the form and size of the workpiece.

In another process of assembling screws to the workpiece, depending on the screw size, there are 5 kinds of holders for carrying screws and guides for preventing screws from dropping, and they can be quickly replaced by using the Button-Locking Pins.

These fasteners only require inserting the pin or pushing the button, so the changeover can be completed easily and in a short time.

The easy changeover process also reduces the machine operator’s workload, as there are many parts that need to be replaced in a single changeover.

They will keep continuing the development of automated machines that allow quick and easy changeovers to reduce the costs and the workloads.

We’re happy to talk to you about IMAO products.

Simply complete this contact enquiry and we’ll be in touch by your choice of email or phone. Thank you!

We know what we’re talking about.

Our directors are at the front lines of all customer requests. They are engineers with experience who meet with you. They have first-hand knowledge in their fields and are always on the lookout for the latest, proven high quality advancements for factory automation.

You’ll find the most popular products specific to leading automation component manufacturers here on the Romheld website. Watch video clips for product demonstrations when available on specific product pages and feel free to visit the manufacturers’ website for more information. You’ll find a complete list at Our Suppliers.