SCHUNK ELG electrical parallel gripper to custom and configure with superior gripping force

With gripping force of up to 12, 000 N and up to 400 mm stroke per finger, this long – stroke electrical gripper meets a range of applications with 12 products and variants available off the shelf.

Long gripper fingers with superior gripping force

This electric 2-finger parallel gripper with long jaw stroke is fully customised and configurable to deliver high gripping force with profiled rail guidance. The ELG fits a range of applications with the gripper working in clean to slightly dirty environments. A single servomotor drives the ball screw via a toothed belt to linearly move the base jaws connected to the spindle nuts and profiled rails. For asynchronous fingers two servomotors can be fitted. Most servomotor brands can be adapted

Schunk ELG at-a-glance offers:

- High flexibility with a long jaw stroke and high gripping force

- Adaptable drive motor for versatile approach and easy integration into existing controls

- Position and torque-controlled movement of the gripper for various geometries and types of components

- Long gripper fingers deliver performance from the profiled rail guide

- Application specific standard gripper has variants and options for customization

Video demo of handling large workpieces with the long-stroke ELG gripper

Romheld Automation distributes Schunk ELG parallel long-stroke grippers to improve machine automation. Along with the Schunk experts, we can help you select the right configuration and walk you through best options for any applications.

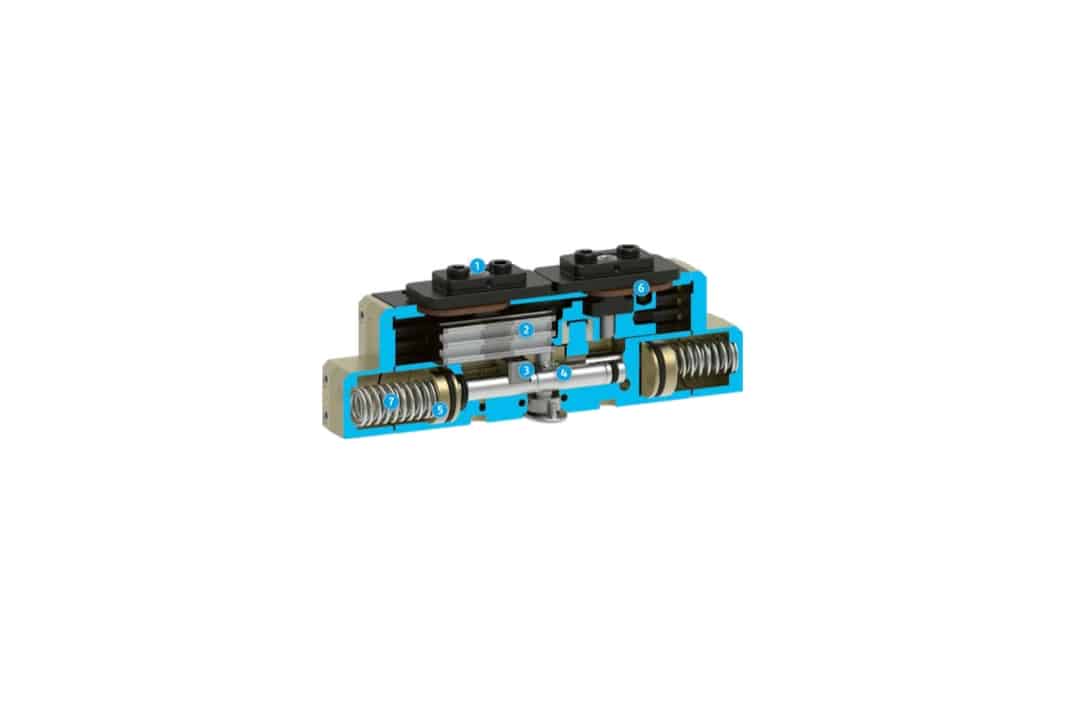

SCHUNK PGL is the pneumatic version of EGL

The pneumatic 2-finger parallel gripper with large stroke, high gripping force and profiled rail guide can be customised and configurable for clean to slightly dirty environments. It is highly flexible with application-specific variants and options.

By pressure actuation of the opposing piston, the base jaws are guided by a carrier on the piston and are set in motion. The synchronisation of the jaw stroke is done with a rack and pinion principle.

The stroke per jaw can be configured to customer specifications between 100mm and 400mm per jaw with millimeter precision.

For full customisation details.

We’re happy to talk to you about any SCHUNK product.

Simply complete this contact enquiry and we’ll be in touch by your choice of email or phone. Thank you!