WEH Leak & Pressure Test Connectors

Automate Vehicle Component Testing

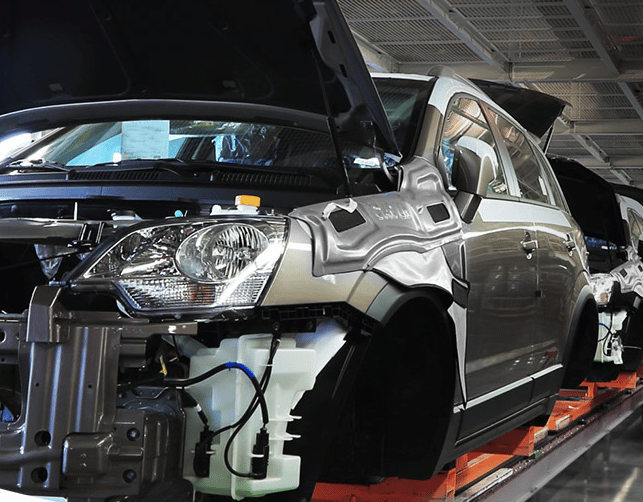

In the automotive industry there are lots of components that need to be checked during the production for proper sealing and correct functioning without disrupting the production process.

Because often very high quantities have to be tested, efficiency, quality, performance and costs are important factors.

WEH® Test Connectors combine these four key factors and provide you significant advantages:

- DIRECT connection – WITHOUT tedious hand tightening

- No need for costly test apparatus

- Large variety of connection possibilities

- Faster connection times & simplified workflows

- Saves time & money

- Automation possible

WEH® Quick Couplers allow for safe & easy pressure and leak testing during series production of automotive components. Benefit from:

Simplified testing – Reduced connection time – Increased productivity

Connect in seconds to female threads, male threads, straight tubes, bores, beads, collars, flanges etc. – without tedious hand tightening.

Connection solutions for vaccum testing / leak testing / helium testing of fuel lines, motors, air conditioning systems & heat exchangers & cooling systems, compressors, cylinder heads, injection pumps, servo-assisted steering systems, fuel tanks, tube connections, automatic production test benchs and transmission systems.

WEH Test Connectors are also used in the field of electric mobility, e.g. for testing batteries, electric motors, cooling and water connections as well as oil modules of electric motors, inverters, power electronics, solar batteries, aluminium boxes with lithium-ion accumulators.

We’re happy to talk to you about any WEH product.

Simply complete this contact enquiry and we’ll be in touch by your choice of email or phone. Thank you!