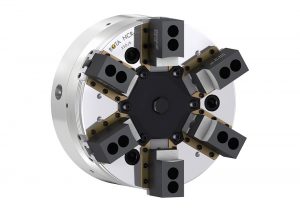

Major milestone with 6-jaw chuck from Schunk

Sealed Schunk 6-jaw chuck with pendulum compensation

Perfect centering and maximum concentricity

The SCHUNK ROTA NCR-A consists of a central chuck piston carrying three inner pendulums aligned at 120°. Each pendulum is connected to two base jaws. This ensures workpiece centering between six contact points, which can be adjusted in pairs. As the clamping forces are directed towards the chuck center, optimal centering is achieved without distortion of the workpiece.

The chuck perfectly adjusts to the workpiece with its oscillating jaws. With conventional jaw clamping, this configuration allows for maximum concentricity of the workpieces and ensures optimal centering at the same time. In the case of ring-shaped workpieces, deformation is reduced by a factor of 10 as compared to clamping with 3-jaw chucks.

Users can also clamp the pendulum of the ROTA NCR-A in the center position during the final processing stage or when clamping pre-turned surfaces so that all six jaws move concentrically. The clamping force between the first and second clamping can be adjusted by a pressure reduction at the hydraulic cylinder. An extremely rigid chuck body and long jaw guidance ensure high repeat accuracy and precise results.

See the full story on the Schunk website: https://schunk.com/pl_en/news/highlights/notifications/article/3584-sealed-6-jaw-power-lathe-chuck-with-pendulum-compensation/

Vast Schunk chuck jaw selection

Standard jaws can be used to replace elaborate system jaws and special solutions on the ROTA NCR-A jaw interface. This saves both time and cost-intensive special solutions, increases flexibility, and reduces set-up costs. Because of its high precision, it is possible to eliminate entire production steps, for example, by reaching tolerances during the finishing process that would otherwise only be reached in complex grinding operations. Since the chuck has a very flat design, and there is plenty of space in your machine for the workpiece and the machining process.

Need more information about the Schunk 6-jaw chuck or other options? We can help. Call us or drop a note on Contact Us.

READY TO TALK TO ROMHELD?

We want to help you find the best product or system solution. Call us on 1800 465 348 or tell us more in an email at Contact Us.

Looking for specific product technology?

Our latest news

We’re happy to talk to you about ordering any of these Schunk products

Simply complete this contact enquiry and we’ll be in touch by your choice of email or phone. Thank you!