SCHUNK is adapting grippers specifically for cobots on the market

Cobots are still considered to be a niche product in robotics, but more and more manufacturers are entering this segment – like large players in industrial robotics as well as specialised cobot pioneers.

We at Romheld have been watching how our suppliers evolve in this niche. SCHUNK has been a front-runner with ready-to-use Plug & Work portfolios that radically simplify equipment for the cobot front end.

Plug & Work simplification puts cobots within easy reach

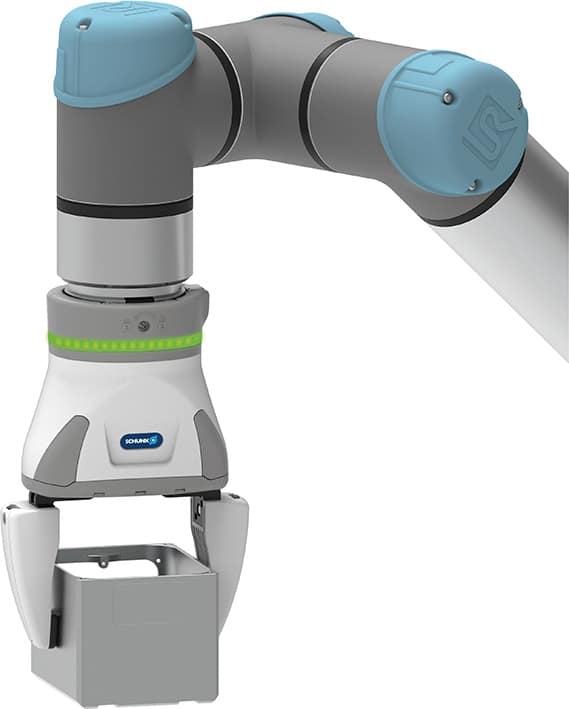

With its freely programmable stroke and rapid commissioning and programming, the flexible SCHUNK Co-act cobot gripper EGH enables easy entry into the world of cobots.

Source here.

Cobots have helped bridge the knowledge gap and budget restraints in adopting robotics for many manufacturers. Suddenly, users who never had anything to do with robots feel confident enough to create an application. Even large automation-savvy corporations are bringing on smart, lightweight robots, because applications have opened up to ease the investment in this new breed of robot technology.

Construction, configuration, design, assembly and installation have been radically simplified by cobot or lightweight robot manufacturers.

“They cost less than standard industrial obots and are significantly easier to program,” explains Benedikt Janssen, Head of Product Sales Mechatronics at gripping/clamping technology expert SCHUNK. “They enable smaller companies to make a low-level entry into robotics with a sensible approach to safety considerations.”

“Traditional industrial robotics are implemented by system integrators and plant manufacturers, who especially appreciate SCHUNK’s large gripping system portfolio and the high quality grippers and end-of-arm components. Now our front-end range for cobots, which are primarily distributed via cobot manufacturers (and Romheld Automation), needs to be much leaner and more universally usable.”

Plug & Work Portfolios bundle components for 80% of all cobot applications

Since introducing Plug & Work pieces for Universal Robots in 2018, a core goal for SCHUNK has been to enable users to achieve productive results quickly and cost-effectively. Combining SCHUNK’s expert knowledge of portfolio components, customers can avoid over-engineering in both conventional automation and collaborative pplications. These are solutions that work well for newcomiers to automation as well as for professionals in the metal-cutting, automotives, electronics and many other industries.

With a variable adjustable total overall stroke of 80mm, the SCHUNK EGH can handle various parts.

Great example: The SCHUNK EGH flexible parallel gripper to cover a wide range of workpieces with a variably adjustable overall stroke of 80mm. Via IO-Link, the finger position can be individually defined, and the gripper status evaluated for each gripper condition. Parallel kinematics ensure constant gripping forces across the entire stroke, while no Z-compensation is required during programming – a distinct advantage over grippers with shear kinematics that are particularly susceptible to faults in the Z-direction.

The SCHUNK EGH is available as a starter kit completely pre-assembled with the appropriate interface and plug-ins for various cobots. Within 30 minutes, users can commission and program these components easily.

Sensitive long-stroke gripper for automated machine loading

For demanding applications in harsh environments like automated machine loading, look at the robust mechatronic long-stroke gripper SCHUNK EGL which enables variable gripping forces between 50 N and 600 N with a freely programmable maximum stroke of 42.5 mm per finger. With force-fit gripping, the intelligent gripper with electronic protection class IP 65 enables process-reliable handling of various, alternating parts of up to 3 kg – including parts that are heavy or are sensitive to deformation. In the case of a power failure, an electrically activated brake ensures that the position of the gripper fingers is maintained and no referencing is required.

SCHUNK is also pursuing consistent simplification of the EGL. Due to the supplied plug-ins for cobot controllers, software-based commissioning of the SCHUNK EGL is possible within just fifteen minutes.

For pallet handling, SCHUNK includes the slim, interfering contour-minimized quick-change module SCHUNK NSR-A in its Plug & Work portfolio. Low attachments to the SCHUNK VERO-S clamping station and pallet are feasible, and there is enough space for the components and the robot motion. For pneumatic, electric and fluid supply of the clamping devices, handling, and assembly tools, the module can also be equipped with standard media transfers.

For more information, see the original SCHUNK article here or talk to Romheld Automation on 1800 465 348.

READY TO TALK TO ROMHELD?

We want to help you find the best product or system solution. Call us on 1800 465 348 or tell us more in an email at Contact Us.

Looking for specific product technology?

Our latest news

WEH TW111

Service Connector for filling refrigerants now on special!

We’re happy to talk to you about ordering any of these Cobot products

Simply complete this contact enquiry and we’ll be in touch by your choice of email or phone. Thank you!