Automated screw feeding with a minimum of particles

An important screw feeding product update on the Stoger step feeder from Stoger Automation. See what a difference this makes for gentle fastener self-feeding compared to a more common vibratory hopper with less friction between screws. This clean and careful screw feeding part helps avoid damage to the coatings used on many fasteners these days.

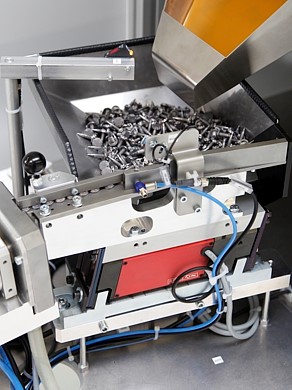

Watch this in action as the rail vibrates to position fasteners correctly for automatic feeding.

STF series screw feeding for a gentle process

Stoeger Automation has long been recognised as a leader in screwdriving, riveting and feed technology. Here’s news on their step feeder system, a technically sophisticated device to process screws, pins, nuts and other fasteners. This is good news for screws with surface coatings because the system is great for applications demanding a clean environment.

The feed unit works like this: fasteners are filled in a funnel-shaped container. Slides transport the fasteners onto a sorting section at the top edge of the container. Correctly positioned and sorted fasteners are transferred to the feed tube via an escapement.

This screw feeding system handles screws gently because vibration only arises on the sorting section. Slides only work if the sensor on the linear section signals a requirement for screws. All parts that come into contact with the fastener are designed for long service life and produced from hardened tool steel.

The feed unit can be optionally expanded to include various sensors and accessory parts.

READY TO TALK TO ROMHELD?

We want to help you find the best product or system solution. Call us on 1800 465 348 or tell us more in an email at Contact Us.

Looking for specific product technology?

Our latest news

Step Feeder advantages at a glance

- Gentle screw feeding handling

- Suitable for the majority of fasteners

- Low noise emissions

- High output

- Rapid clearance of non-dimensionally compliant or deformed screws & foreign bodies

- Can be operated from 100 to 240 V (50 / 60 Hz) without additional settings or modifications

- Cover of the sorting chicane is simple to remove without tools, e.g. for maintenance purposes

- Different screw batches can be balanced with the sorting equipment settings

- UL-approved components according to DIN VDE

Step Feed accessories also available

Hopper ensures gentle fastener handling, increases autonomy time and fills volumes from 3 to 50 litres.

Escapement / Distributor allows targeted feeding and supplies either multiple screwdriving units in parallel or one spindle with different fasteners

Optical contents level control ensures controlled refilling of fasteners, low wear and avoids particles forming due to reduced movement.

CAD data and further information are available on the Stoeger website.

See our page on all other Stoger Screwdriver Systems.

We’re happy to talk to you about Stoger products

Simply complete this contact enquiry and we’ll be in touch by your choice of email or phone. Thank you!